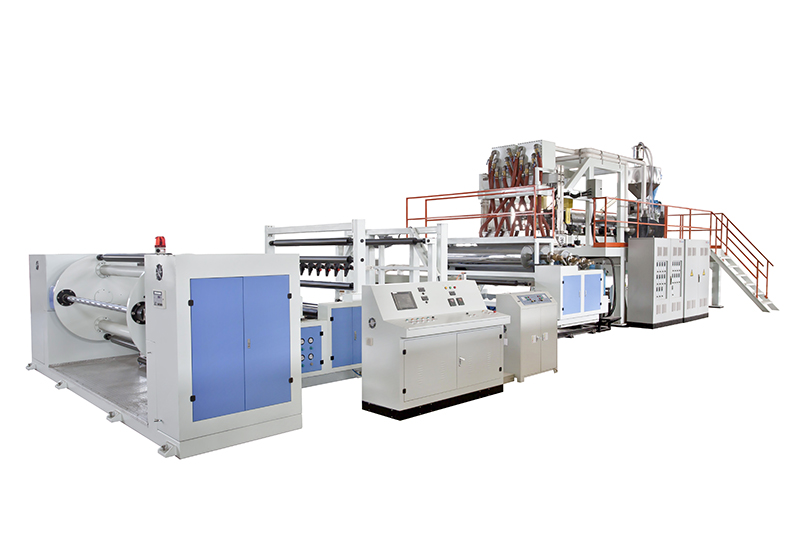

Cam khwb cia Embossed zaj duab xis kab, Hygiene zaj duab xis kab

* QHIA

Cam khwb cia embossed zaj duab xis kab tsim yaj embossed zaj duab xis rau kev tu cev, kev kho mob thiab ntim daim ntaub ntawv.Qhov zoo tshaj plaws tsim ntawm extruder thiab T tuag guarantees high-kev ua tau zoo extrusion thiab ntau theem ntawm nta thiab automation muaj nyob rau zoo tshaj plaws raws li koj xav tau kev pab.

Lub extruder converts polymers mus rau hauv nruam yaj resin, thiab ces T tuag ua nws li zaj duab xis ntaub.Los ntawm xws li ib tug cam khwb cia zaj duab xis extrusion system, ib tug engraved steel yob thiab silicon roj hmab yob yog ntsia ntawm lub laub casting ntawm txoj kab.Thaum cov ntaub nplaum yaj tawm los ntawm T tuag, nws yog nias rau ntawm embossing yob los ntawm silicon yob los tsim embossed zaj duab xis.Cov yeeb yaj kiab embossing qauv tuaj yeem tsim raws li cov qauv uas twb muaj lawm lossis cov neeg siv khoom thov.Kev hloov pauv ntawm cov qauv embossing yog nrawm thiab yooj yim los ntawm kev hloov cov calendaring rollers nkaus xwb.Raws li qhov tshwm sim ntawm embossing nto, lawv yog cov yeeb yaj kiab kev siv hauv ntau qhov kev lag luam.Wellson Machinery muaj ntau xyoo dhau los ntawm kev tsim cam khwb cia embossed zaj duab xis kab rau cov neeg siv khoom thoob ntiaj teb.Peb cov thev naus laus zis thiab kev paub zoo pab peb cov neeg siv khoom los tsim cov khoom muaj nqis ntxiv rau kev lag luam.

Peb cov cam khwb cia embossed zaj duab xis tshuab yog ua thiab tswj los ntawm advanced PLC system thiab HMI system.Peb cov cav tov yog kev sib xyaw ua ke ntawm kev ua haujlwm siab thiab kev siv hluav taws xob tsawg vim yog kev tsim tshuab siab heev.Lawv yog cov kev daws teeb meem zoo tshaj plaws rau cov neeg tsim khoom ntawm kev ua yeeb yaj kiab

* KEV PAB CUAM

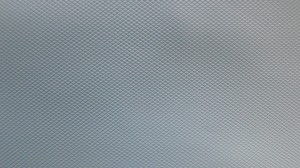

Melt embossing txheej txheem muaj ntau yam kev siv, xws li PE zaj duab xis rau tus me nyuam daim pawj, cov ntaub so ntswg huv, cov khoom tsis yooj yim, cov ntaub so ntswg, cov ntaub so ntswg pov tseg, cov ntaub so ntswg kho mob, loj hlob, hnab looj tes, khau npog, roj hmab tso zaj duab xis, rooj ntaub, da dej ntaub, thiab lwm yam.

Melt embossed PE zaj duab xis feem ntau yog siv los ua kev nyiam huv backsheet zaj duab xis rau tus me nyuam daim pawm, cov ntaub so ntswg huv, cov neeg laus cov pawm, hauv qab.Peb muaj kev paub ntau tshaj plaws hauv kev tsim cam khwb cia embossed zaj duab xis tshuab kom tau raws li cov kev xav tau ntawm kev tu cev thiab PE zaj duab xis rau cov khoom siv kho mob pov tseg xws li cov ris tsho phais, cov ris tsho cais tawm.

* TECHNICAL DATA

| Qauv No. | Ntsia Hlau Dia. | Tuag dav | Zaj duab xis dav | Zaj duab xis Thickness | Kab Ceev |

| FME120-1600 | ¢ 120 mm | 1900 hli | 1600 hli | 0.02-0.15 hli | 200m / min |

| FME125-2000 | ¢ 125 mm | 2300 hli | 2000 hli | 0.02-0.15 hli | 200m / min |

| FME135-2500 | ¢ 135 mm | 2800 hli | 2500 hli | 0.02-0.15 hli | 200m / min |

Lus Cim: Lwm qhov ntau thiab tsawg ntawm cov tshuab muaj nyob rau ntawm kev thov.

* NTA & ADVANTAGES

1) Txhua zaj duab xis dav (txog 4000mm) ntawm cov neeg siv khoom pov tseg.

2) Yooj yim hloov embossing yob rau ntau yam emboss qauv.

3) Tsawg heev variation ntawm zaj duab xis thickness

4) In-line zaj duab xis ntug trim thiab recycling

5) In-line extrusion txheej yog xaiv tau

6) Nws pib zaj duab xis winder nrog ntau qhov sib txawv ntawm huab cua ncej